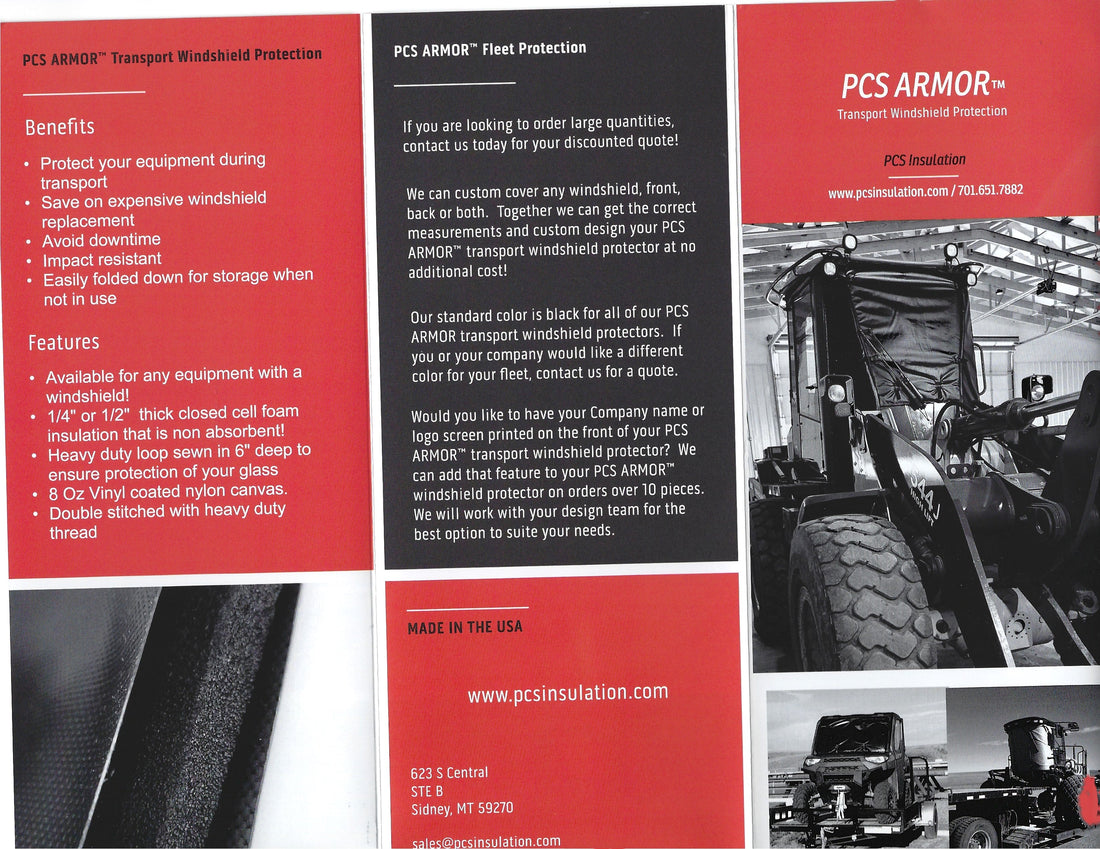

Removable Insulation

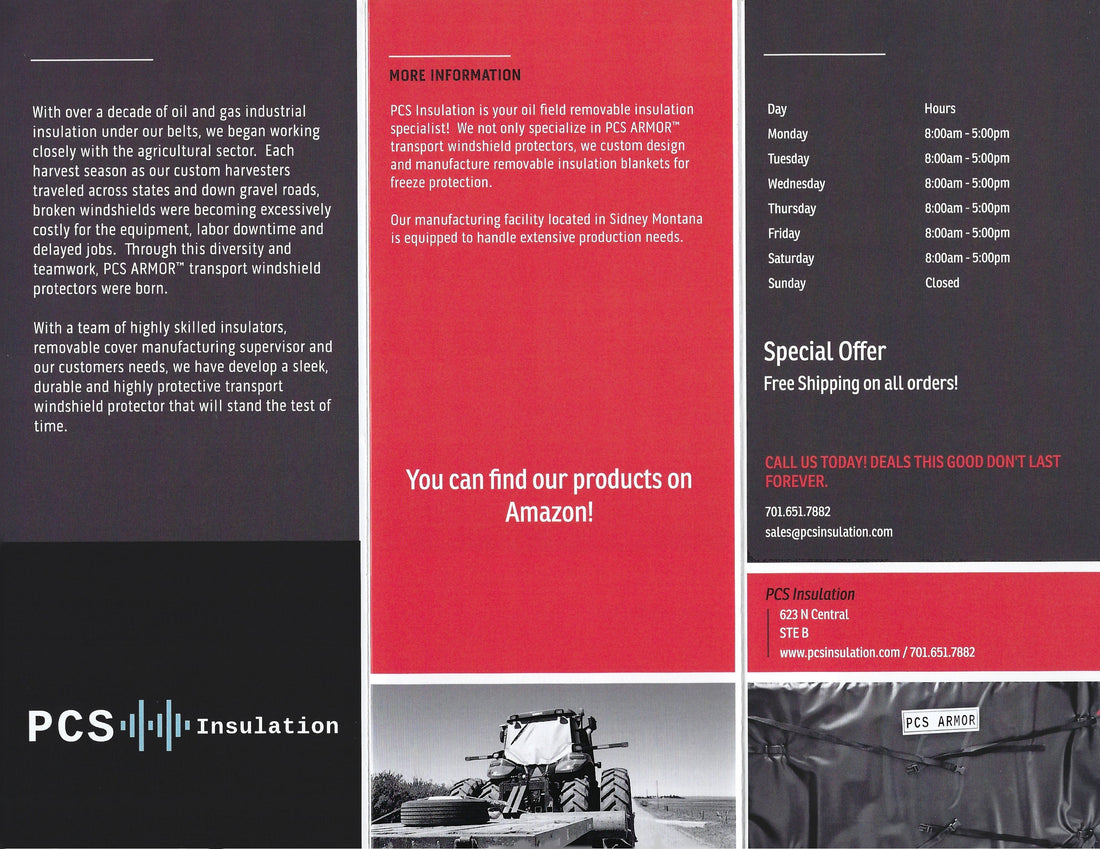

PCS Thermal, is our brand of removable insulation designed to keep your industrial process systems flowing. Our thermal products can also help reduce greenhouse emissions, reducing BTU's consumed with proper insulation will lead to less carbon dioxide emissions.

Removable insulation is commonly used in Marine, Oil & Gas, Power Generation, Agriculture, Industrial, Military, Mining, Exhausts and more. These industries use removable insulation for a variety of reasons including: sound absorption, freeze protection, personal protection, high heat areas and operator ease just to name a few.

When it comes to the design of your product, you will have a dedicated project manager regardless if it is one blanket or 3,000 blankets. Our personal touch, dedication to high quality products and affordable products manufactured in Eastern Montana is why our customers choose us over the competition.

We take great pride in manufacturing an American made product, using as many local components as possible to support the local economy. Our team has been dedicated to serving the North Dakota and Montana oil fields, saltwater disposals and midstream sectors.

There are several types of removable insulation blankets. The most common are:

- Removable insulation blankets for hot components

- Removable insulation blankets for cold components

- Removable insulation blankets for freeze prevention

- Removable insulation blankets for sound attenuation

WHY USE REMOVABLE INSULATION

PCS removable insulation blankets are often referred to as jackets or pads and consist of layers of thermal insulation materials. Removable insulation blankets slow the transfer of thermal energy and focus on how well a material resists the flow of heat while allowing operator ease to removal and installation. This method is extremely valuable on fittings that require inspections and maintenance

DIFFERENT LAYERS OF REMOVABLE INSULATION

Removable insulation blankets can be divided into 2 main components:

- An outer protective cover designed to shield and protect the insulation from the environment in which it finds itself.

- The insulation mat itself, typically 2″ thick fiberglass, provides the actual heat containment. Thicknesses vary from ½” up to 4” depending on the amount of heat reduction the application requires

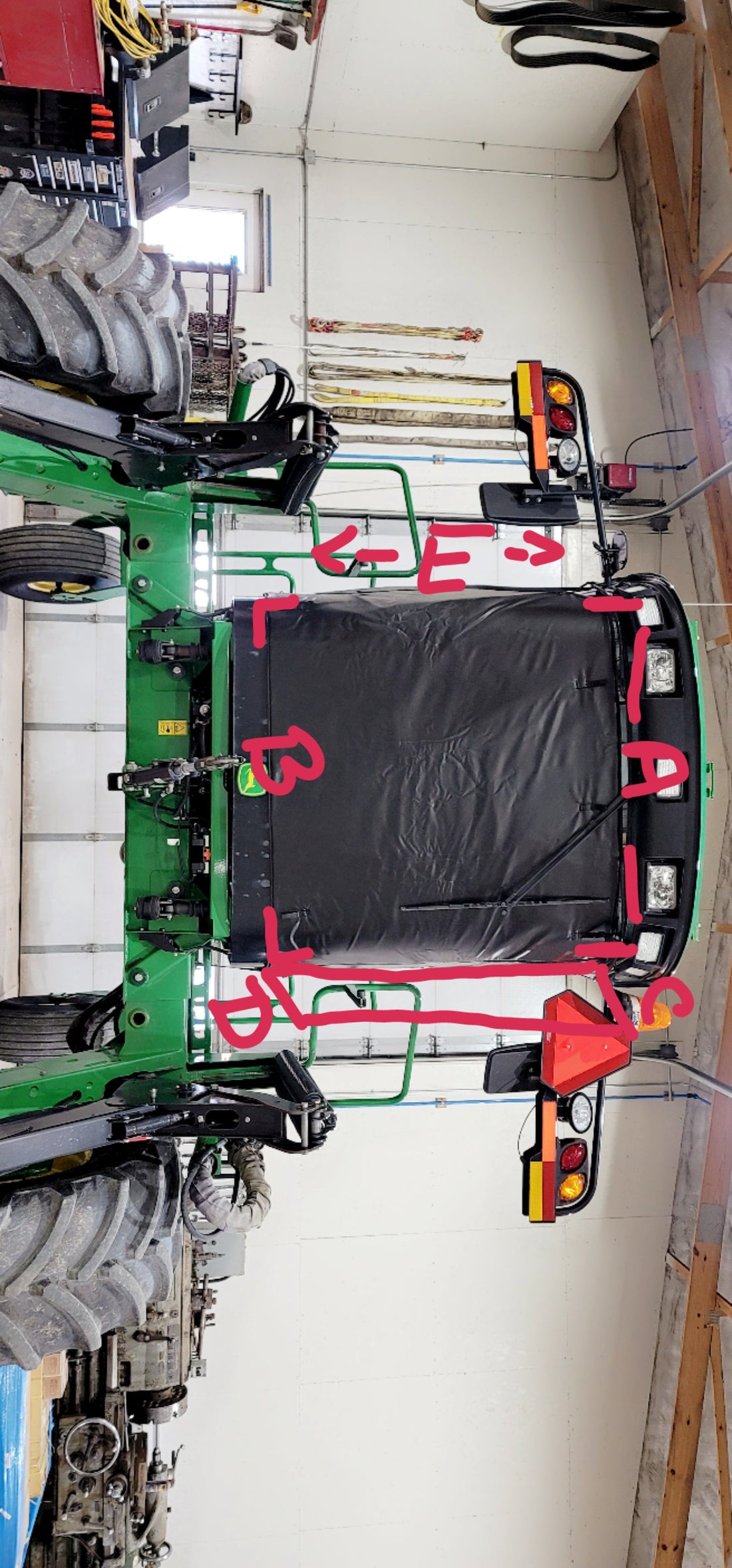

Aside from these 2 components, there is the fastening system which is used to secure the insulation blankets in place. The type of fastening used is dependent on the type of equipment being covered, the applications for which it will be used, and the environment in which the covered equipment operates. A wide variety of fastening equipment is available for use with removable insulation blankets. Common fastening methods include:

- Velcro

- Lacing Wire

- Straps

- Springs